UV Lighting from MBJ

The UV High Power series is available as bar and ring lighting in various sizes for different inspection focuses, e.g:

- Inspection of the smallest details on surfaces, e.g. solder joints, cut surfaces

- Use of fluorescence for print image inspection or differentiation of materials

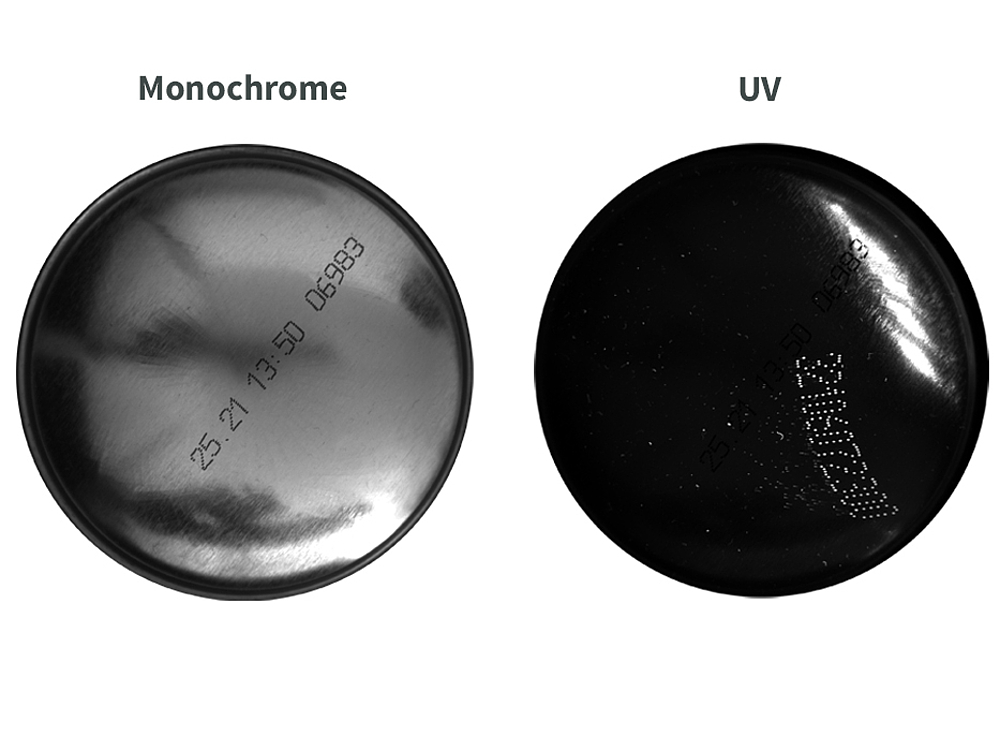

Inspection of the smallest details

One type of application can be UV reflection. Here, the reflection of the emitted (non-visible) wavelength in the UV range is evaluated. UV is a short-wave light and produces stronger reflections than longer-wave light (e.g. infrared). UV reflection is therefore suitable for inspecting the smallest details on surfaces, such as solder joints or cut surfaces. However, certain materials and features can also be examined using classic absorption of light.

This type of inspection is suitable for the following materials:

- Materials that strongly absorb certain wavelengths and create contrasts over them

- Materials that strongly reflect short-wave light (UV) and are therefore particularly good at detecting defects.

A UV-sensitive camera is required to use direct UV light.

Visibility through fluorescence

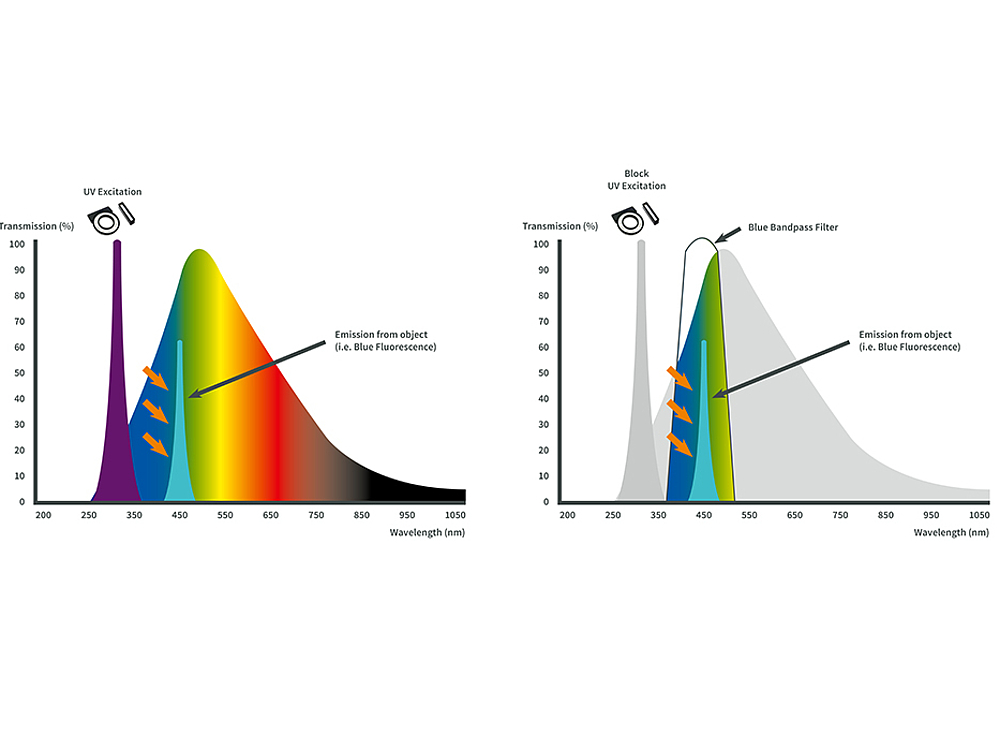

The most common application for UV wavelenghts is fluorescence. UV wavelengths are very high-energy, so they can excite certain materials to emit at a different, visible wavelength (to fluorescence). This effect or the shift between the exciting and the emitted wavelength is called "Stokes Shift".

Since in fluorescence applications it is usually not the UV wavelength itself that is examined, but the emitted, visible wavelength, the use of a special UV camera is not usually necessary.

This type of inspection is particularly suitable for

- Detection of fluorescent print markings (printed products, leak tests

- Differentiation of visually indistinguishable materials (e.g. transparent adhesives, fiber mixtures)

It should be noted that the energy level of the wavelength emitted by the test material is lower than that of the exciting UV wavelength and correspondingly high intensities of the UV wavelengths are required.

Use of filters with UV lighting

The UV wavelength typically stimulates the fluorescence of blue, green or, more rarely, red wavelengths.

Camera filters that filter out both the UV wavelengths and the unused visible wavelengths (bandpass filters) increase the image quality. Superfluous information is not even recorded and the fluorescent wavelength can be clearly evaluated.

A combination of illumination filters and camera lens filters can further optimize the results, as an exact separation of the excitation and emission wavelengths is made possible.

- UV reflections from the illumination and extraneous light influences are suppressed

- The use of bandpass filters minimizes the influence of extraneous light

It may be worth considering the use of a color camera, which allows the fluorescence to be seen more clearly in some cases.

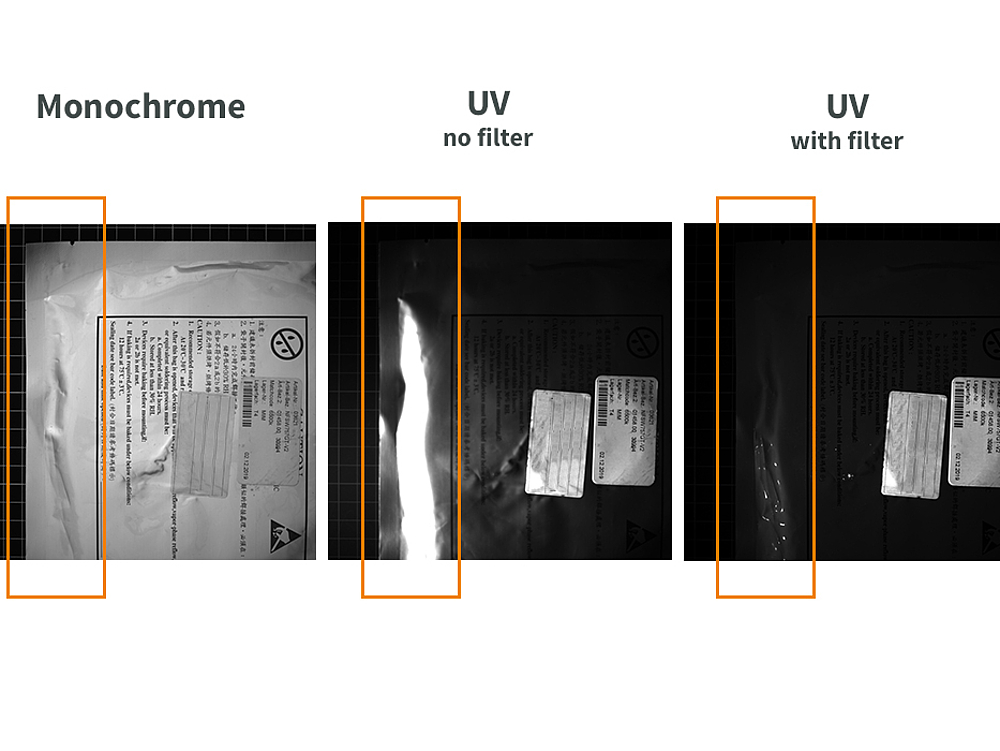

Example of a filter insert:

In a typical fluorescence application where the color cyan is emitted, a bandpass filter with a wavelength of 470 nm or 505 nm allows the light/wavelength of cyan to pass through and blocks all other wavelengths, limiting unwanted colors and ambient light in the image. In the example shown, the filter insert reveals the fluorescent areas that mark where the aluminum coating of the packaging has been damaged.